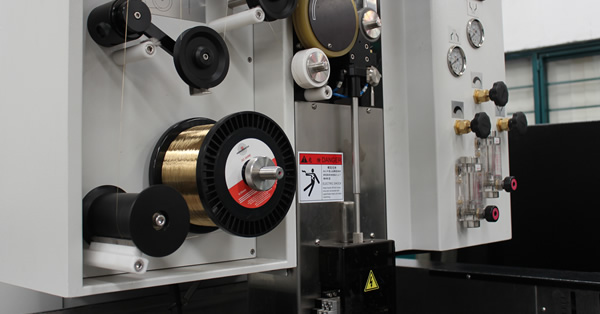

EDM wire cutting

An electrical spark is created between an electrode and a workpiece. The spark is visible evidence of the flow of electricity. This electric spark produces intense heat with temperatures reaching 8000 to 12000 degrees Celsius, melting almost anything. The spark is very carefully controlled and localized so that it only affects the surface of the material. With wire EDM the spark always takes place in the dielectric of deionized water. The water acts as a coolant and flushes away the eroded metal particles.

EDM wire cutting uses a metallic wire to cut a programmed contour in a workpiece. Extrusion dies and blanking punches are very often machined by wire cutting. There is never any mechanical contact between the electrode and workpiece. The wire is usually made of brass or stratified copper, and is between 0.1 and 0.3 mm diameter.

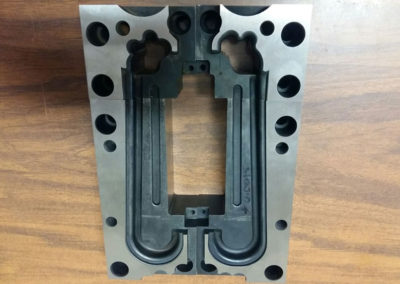

Sinker EDM Machining Process

The sinker EDM machining (Electrical Discharge Machining) process uses an electrically charged electrode that is configured to a specific geometry to burn the geometry of the electrode into a metal component. The sinker EDM process is commonly used in the production of dies and molds.

Two metal parts submerged in an insulating liquid are connected to a source of current which is switched on and off automatically depending on the parameters set on the controller. When the current is switched on, an electric tension is created between the two metal parts.

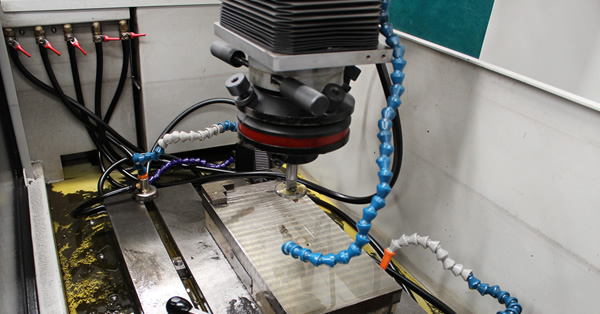

Conventional Machining Center

We have machine tools such as:

Turning machine

Operations with turning includes tapered turning, spherical generation, hard turning, facing, parting, grooving, boring, drilling, knurling, reaming, threading and polygonal turning.

Milling machine

Radial Drilling Machine

There are a number of advantages of using the radial arm drill press. One of these advantages is the amount of area that it can cover which is only dependent on the length of the arm. Another advantage is the considerable size of work that it can handle since the arm can actually swivel out of the working area allowing cranes and derricks to place work pieces on the table. Finally, less effort is required during the drilling process because the arm assembly seemingly is doing all that is needed for specific tasks to be completed.

Flat Grinding Machine

Depending on the workpiece material, the work is generally held by the use of a magnetic chuck. This may be either an electromagnetic chuck, or a manually operated, permanent magnet type chuck; both types are shown in the first image.

The machine has provision for the application of coolant as well as the extraction of metal dust (metal and grinding particles).

Cylindrical Grinding Machine

Cylindrical grinding is defined as having four essential actions:

- The work (object) must be constantly rotating

- The grinding wheel must be constantly rotating

- The grinding wheel is fed towards and away from the work

- Either the work or the grinding wheel is traversed with respect to the other.

Special Welding Machine (See Photos)